Reports and articles

How can SMEs play a greater role in tech adoption?

Published on June 22nd 2023

Technology diffusion plays a vital role in the growth and competitiveness of firms. By adopting new technologies, businesses can become more productive, improve communication, automate processes, and seize new opportunities. This leads to greater efficiency and differentiation, benefiting both the firms and the economy.

However, a productivity gap persists – in part – due to slow technology adoption, favouring large firms that have better access to skills, finance, information, and tech capabilities. This concentration of power reduces competition in the market over time. To address this, it is important to involve small and medium-sized enterprises (SMEs) in the positive cycle of technology adoption and productivity.

In this blog, we explore how policy intervention is necessary to overcome barriers such as limited access to capital, skills, information, and support. And drawing on examples from Japan and the USA, illustrate how dedicated technology diffusion institutions can bridge the productivity gap by providing SMEs with knowledge, resources, and financial assistance.

Technology diffusion programmes and institutions: Lessons from Japan and the USA

Each country has various types of technology diffusion programmes and institutions. In Canada, Global Innovation Clusters support global companies, while Industrial Research Assistance Programme supports SMEs. In Germany, the Fraunhofer Society supports technology diffusion throughout its 76 institutes and research units distributed throughout the country. Technology diffusion systems vary widely depending on a country’s industrial structure, policies, and institutional history.

Here, we look at examples from Japan and the US to see how technology diffusion is supported by SMEs and the role this plays in national technological capability.

Japan

Japan is a leading industrial and technology power, with manufacturing contributing 20% to GDP. A reason for the high level of technological capacities is technology diffusion for SMEs. The key institution is the Organization for Small and Medium Enterprises and Regional Innovation (OSMERI), also called SME Support.

OSMERI is an independent administrative organisation managed by the Ministry of Economy, Trade, and Industry (METI). The organisation provides various supports, such as hands-on consultation and the transition to digitisation and smart manufacturing. As the national government governs it, it provides uniform service in all its branches across the country.

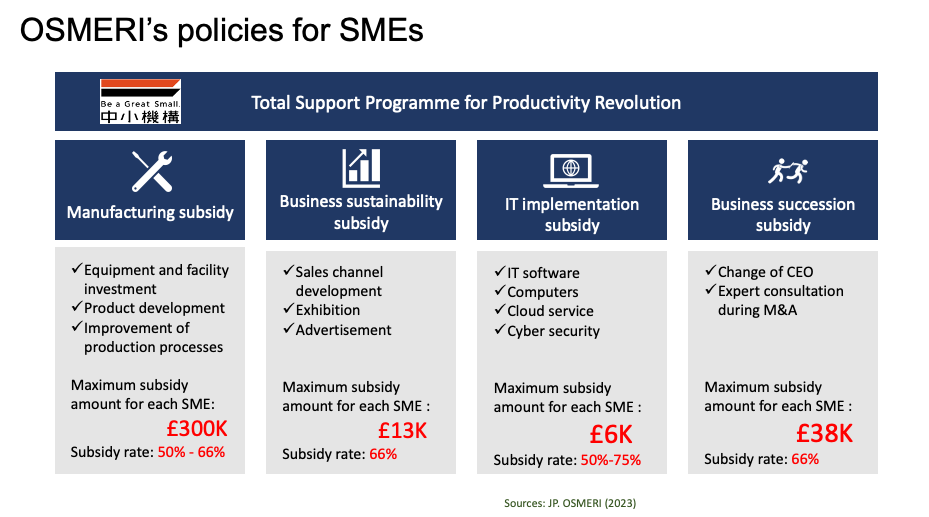

In addition, OSMERI offers the Total Support Programme for Productivity Revolution to SMEs. This consists of four subsidies with a total annual budget of GBP 1.6 billion: manufacturing subsidy, business sustainability subsidy, IT implementation subsidy, and business succession subsidy.

The combination of these subsidies greatly facilitates technology diffusion among SMEs. For instance, in an ageing Japanese society, it would be opportune to receive IT implementation and business succession subsidies when there is a change of management, as younger CEOs are more familiar with IT and digital technology.

Furthermore, this total support programme is successful in the way of spreading awareness. By working with local newspapers and banks, it has extended its reach to CEOs of SMEs in regions. This is because they value deep-rooted local ties.

Thanks to this programme, a cumulative total of about 200,000 SMEs in Japan annually receives technology diffusion support.

USA

In the United States, the key technology diffusion institution that supports small and medium-sized manufacturers with technology and business practices is Manufacturing Extension Partnership (MEP).

MEP was established in 1989 to boost the competitiveness of American manufacturers by spreading existing technologies to small and medium manufacturers. It operates through 51 centres in all 50 states and Puerto Rico with one primary local partner each, and receives funding from the government, consulting fees, and contributions from individuals and institutions. The government funding for MEP is increasing as the US aims to promote domestic manufacturing.

MEP centres provide various services tailored to the needs of small manufacturers, including advice, training, and sometimes financial assistance. Each centre operates with a CEO, a board of directors, and field specialists, allowing them to function autonomously. MEP delivers services through in-house specialists (MEP specialists directly assist manufacturers) and broker models (connects them with external consultants).

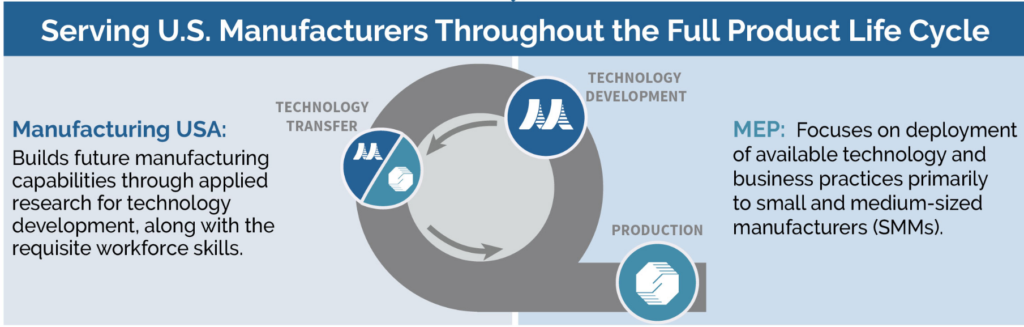

MEP also collaborates with Manufacturing USA to introduce small manufacturers to new technologies. Manufacturing USA is a research organisation that focuses on developing innovative technologies, and MEP acts as a bridge to help small manufacturers adopt and benefit from these technologies. For example, WarmLife Panels, an early-stage startup developing radiant panels that provide clean, energy-efficient heat wanted assistance in selecting technologies for joining dissimilar materials. It reached out to New York MEP, who then contacted Institute for Advanced Composites Manufacturing Innovation (IACMI), a Manufacturing USA research institute. IACMI and WarmLife agreed on a technology partnership and eventually settled on snap-and-click design for prototype testing.

MEP conducts annual evaluations to assess the impact of its policies on the economy relative to the funding it receives. This helps MEP secure and improve on funding.

Overall, MEP is a network of centres in the US that collaborate with other organizations to support small manufacturers by diffusing technology and business practices. They have helped generate $111.3 billion in new and retained sales for over 94,000 clients in the last 30 years.

Lessons for other countries

Technology diffusion faces numerous barriers, such as limited resources, uncertainty, and resistance to change. SMEs are particularly affected. However, policy interventions in the form of technology diffusion institutions can break these barriers and foster SME growth.

In the UK, for example, these institutions could address productivity gaps by offering support for upskilling employees and enhancing leadership. Countries like Germany have already seen success with such institutions, leading to improved company performance and increased innovation by increasing various dimensions of company performance, including employee headcount, turnover, labour productivity, and share of employees with tertiary education. By facilitating technology adoption, these institutions empower SMEs to thrive and succeed in a competitive landscape.

Drawing on these policy lessons from Japan and the US, the UK and other countries can enhance their effectiveness, reach, and support for SMEs via the following insights and recommendations:

- Policy Assessment: Policy assessment helps understand the impact of policies on businesses and the economy. The MEP conducts annual assessments, while Japan is working to overcome data privacy limitations to do the same. Policy makers in other countries could establish an independent institute to conduct assessments of the support provided to firms and make adjustments where necessary.

- Subsidies and Consultation: MEP offers subsidized consulting services and occasional monetary awards, while OSMERI provides targeted subsidies and low-cost consulting services. Combining subsidies and consultation addresses finance and knowledge access barriers. Technology diffusion initiatives can strengthen its impact by establishing long-term partnerships, introducing diverse subsidy packages, and providing consulting assistance.

- Academic Collaboration: MEP partners with state and federal universities, while OSMERI collaborates with SME universities. University partnerships provide expertise, manpower, and awareness. Other countries may also consider partnerships with university departments to create mutual benefits for SMEs and students.

- Institutional Structure: OSMERI is highly centralised with standardised offerings, while MEP is decentralised. Centralisation provides control and cost reduction, while decentralisation offers personalised services. Those in charge of technology diffusion should consider a centralised structure for institutional decision-making, standardisation of services and diffusion of knowledge across centres while decentralising the authority for daily operations and decisions to regional centres.

- Spreading Awareness: OSMERI uses YouTube, chatbots, free initial consulting, CEO seminars, and local newspaper and bank partnerships. Technology diffusion institutions can employ chatbots, offer free initial meetings, establish local partnerships, leverage digital marketing, and engage SME communities through networking events.

For further information please contact:

Elizabeth Tofaris

+44 (0)1223 766141ejar2@cam.ac.ukThis blog was based on a project to analyse the technology diffusion institutions in the US and Japan in collaboration with Made Smarter as part of the IfM’s Industrial Systems, Manufacture, and Management (ISMM) programme at the University of Cambridge. It was written by Yukihiro Sato and Aarya Goenka.

Yukihiro Sato is a postgraduate student in the MPhil in ISMM, Institute for Manufacturing, at the University of Cambridge. He previously worked for the Ministry of Economy, Trade and Industry at the Government of Japan.

Aarya Goenka is a postgraduate student in the MPhil in ISMM, Institute for Manufacturing, at the University of Cambridge. He has a bachelor’s in Applied Mathematics from the University of California, Los Angeles.

Related resources

19th February 2026

Unpacking the France–UK productivity gap: a sectoral analysis

13th February 2026

The UK Manufacturing Dashboard: a tool for evidence-based industrial policy

News | 6th February 2026

UK Manufacturing Dashboard: latest performance and global benchmarks

Get in touch to find out more about working with us