Reports and articles

Don’t fear the robots: How developing countries can prepare for Industry 4.0 and safeguard jobs

Published on September 10th 2021

For manufacturing in developing countries, the impact of digital technologies is likely to be slower and less disruptive than feared. But policy action is needed to avoid deepening existing inequalities.

The potential of digital technologies to automate routine tasks and replace human labour can sometimes seem like an existential threat to manufacturing in developing countries, with some reports identifiying up to 85% of jobs as being at risk.

Such predictions tend to be based on technical feasibility. However, the automation of jobs also depends on economic and institutional feasibility, and these factors can outweigh the technical aspects.

Digital technologies are undeniably transforming production systems, trade networks and labour relations; however, the pace of these changes is likely to be slower and less disruptive than many studies have predicted.

Lower labour costs, younger populations, limited infrastructure and skills shortages make a weak economic case for embarking on large investments in automation in developing countries. For example, the World Bank has estimated that, adjusting for lower wages and slower technology adoption, the shares of jobs at risk of automation is reduced by half in countries such as Cambodia and Ethiopia, and by one-third in countries such as Bolivia, Nigeria and Thailand.

And automation can be challenging even in developed countries where firms may find more advanced infrastructure and skills – witness Adidas, which over the past two years has decided to stop operations in the ‘speedfactories’ they opened in Germany and the US just a couple of years previous.

This, however, does not mean that least developed countries and developing countries cannot benefit from new and emerging technologies.

Technological change is happening, both in developed and developing countries, and this trend has been further accelerated by the COVID-19 pandemic. A survey conducted among 3,450 executives across developed and developing countries found that 59% of organisations had accelerated their digital transformation as a result of the pandemic, while 66% reported they had been able to complete digital initiatives that previously encountered resistance.

Our work in Cambodia, Indonesia and with the Commonwealth Secretariat has focused on exploring opportunities that digital technologies can offer to developing countries. These range from the adoption of low-cost, off-the-shelf technology solutions to improve firms’ efficiency and productivity to the delivery of ‘smart’ services and frugal innovations to adapt open source technologies to specific contexts and needs.

Industry 4.0: Beyond the robot hype

Digital technologies enable automation, and this capability has become central in the debate about massive job displacement. However, digital technologies involve more than robots, and their capabilities go far beyond automation.

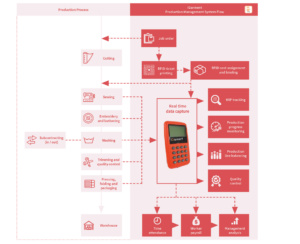

From the different applications of digital technologies, our work has focused on those concerned with industrial manufacturing. These applications, commonly referred as Industry 4.0, concern the integration of the cyber world of information and communication technology, like software and wireless communication, with the physical world of operation technology, like machines and their human operators.

This cyber–physical integration enables automation, but also other useful capabilities, such as decentralisation, virtualisation, real-time response and flexibility. For example, in an ongoing project in Cambodia in collaboration with the United Nations Development Programme (UNDP), we have identified opportunities for improving business efficiency and productivity by leveraging production management systems, both in garment and agro-processing firms. These technological solutions are enabling firms to gather and analyse real-time data on the availability, performance and quality of production lines.

Production management system used by factories in Cambodia

Source / Copyright: iGarment (n.d.). iGarment Production Management System. Reproduced with permission of the company.

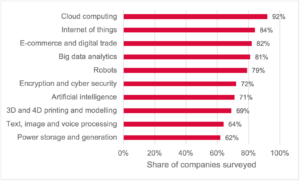

While robots are increasingly being used, there are other and more affordable Industry 4.0 technologies that show higher rates of adoption, and have the potential to create more immediate improvements in company performance. These include cloud computing, the Internet of Things and big data analytics.

Technologies likely to be adopted by manufacturing firms by 2025

During the COVID-19 outbreak, these technologies have gained even more importance. A study conducted by the IBM Institute for Business Value across 20 countries and 22 industries found that, during the pandemic, cloud computing, artificial intelligence and data analytics were larger drivers of business revenues than robotics.

Skills for an inclusive industrial digitalisation

As part of our work in collaboration with the Asian Development Bank (ADB), we conducted a review of international studies which revealed a great deal of variation in predictions of the impact of automation on jobs. Figures go from the creation of over 100 million jobs to the loss of over 200 million. While there may be lack of consensus on the overall net impact on jobs of the adoption of digital technologies, most of these studies agree that there will be winners and losers in this so-called Fourth Industrial Revolution.

The production and trade of new products will create new job opportunities for those who have, or acquire, the relevant skills. Better equipped firms and individuals are already reaping the benefits of Industry 4.0 technologies, and deepening market concentration and social inequality. The COVID-19 pandemic has further exposed these inequalities, affecting certain population groups disproportionally, including the self-employed, women and working people on both extremes of the age curve.

Drivers of competitiveness are also changing. As factors such as environmental sustainability, social responsibility, and supply chain transparency and agility are increasingly important in international markets, the adoption of digital technologies is becoming a prerequisite to participate in global value chains.

Given the rapid pace of technological change, it is imperative that governments work in collaboration with industry, employees, and education and training institutions to ensure that firms and individuals acquire the capabilities needed to participate in the opportunities created by Industry 4.0.

Governments and industry will need to address safety risks emerging from new forms of human–machine interaction and exposure to new materials. However, digital technologies can also be leveraged to improve occupational ergonomics and overall employee safety, reducing the need for humans to do physically hard or dangerous work.

Although uncertainty exists in relation to how new technologies will affect jobs in the future, a clear trend is already being seen: skills shortages. According to The Future of Jobs Report 2020, skills shortages represent the main barrier to the adoption of new technologies. This is a pattern that we have also observed across our projects in both developed and developing countries.

Throughout our work, including consultations with firms and the review of recent trends, we have identified that abilities demanded by firms adopting Industry 4.0 include:

- Digital skills (such as cloud computing, computer networking, cyber-security, data analytics, IT infrastructure management, information management and software development)

- Managerial skills (such as decision-making, leadership, technology trend monitoring, project management and strategic thinking)

- Production skills (such as lean manufacturing, operations management, quality management and supply chain management)

- Innovation skills (such as adaptability, creativity, critical thinking, and engineering and design)

- Other soft skills (such as problem solving, mind-sets for independent and lifelong learning, and communication)

Policy options

Although the massive job displacements predicted by some studies are unlikely to happen, at least not in the near future, there is increasing evidence that the digital divide is deepening economic and social inequalities. Without the right policies in place, developing countries risk being left further behind in the digital transformation journey.

Throughout our work, we have identified three key areas of policy action that can help countries reap the benefits of Industry 4.0 technologies: (i) placing people at the centre of the digital transformation, (ii) easing access to technology, and (iii) improving the institutional framework.

People

Placing people at the centre of the digital transformation involves implementing policies to mitigate negative impacts, including:

- Establishing industry–employee–government–university dialogues.

- Developing programmes for workforce reskilling and upskilling.

- Adopting lifelong learning approaches in vocational training and education.

- Delivering safety net schemes for those losing their jobs.

- Adopting gender-sensitive approaches in policy design and delivery.

- Ensuring compliance with labour regulations.

- Adapting regulations and ensuring compliance with international standards to address new safety and health hazards.

Technology

Although these technologies are becoming cheaper and easier to adopt, lack of information on their availability, benefits and risks can hinder technology adoption. SMEs may also need additional financial and technical support. Activities that can contribute to ease access to Industry 4.0 technologies include:

- Raising awareness of the benefits of Industry 4.0 technologies and cybersecurity threats.

- Financing of technology adoption, adaptation and development.

- Developing business advisory services and technology transfer centres to build firms’ capabilities and support technology adoption.

Institutions

Although skills are one of the main barriers to technology adoption, governments also need to continue their efforts to improve the institutional framework, and to further develop their national innovation systems. Key actions include:

- Updating regulation and ensuring enforcement.

- Creating governance structures for the coordination of national digital policies.

- Improving the business environment (e.g. cutting red tape).

- Investing further in physical and digital infrastructure.

At Policy Links, we work with governments and international development actors to inform the design and implementation of Industry 4.0 and broader industrial innovation policies. We base our work on the latest academic thinking and international best practice. We combine these with careful study of the specific contexts, usually in collaboration with local partners, to identify sound and practical policy options. Find out more about working with us.

For further information please contact:

Jennifer Castañeda-Navarrete

+44(0)1223 766141jc2190@cam.ac.ukConnect on LinkedInRelated resources

News | 6th February 2026

UK Manufacturing Dashboard: latest performance and global benchmarks

3rd February 2026

The Swiss paradox: a services reputation built on an industrial and innovation powerhouse

News | 21st January 2026